servizi

Logimatic Srl - Servizi

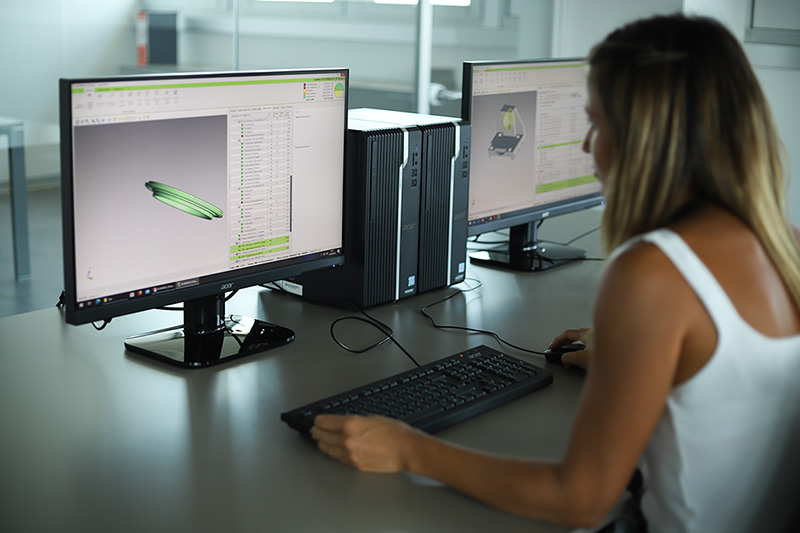

DEFINIZIONE DEL PROGETTO

Sviluppiamo macchine automatiche partendo dal disegno di progettazione dato dal Cliente in qualsiasi formato, cartaceo o elettronico. Durante le diverse fasi del progetto ci interfacciamo con regolarità con il Cliente e collaboriamo insieme per realizzare un prodotto di qualità superiore al miglior prezzo possibile, utilizzando varie tecniche di industrializzazione.

PRODUZIONE DEI COMPONENTI

Coordiniamo una rete integrata di subfornitori che ci permette di produrre i singoli componenti necessari alla costruzione dell’intera macchina o di parti di essa, come da commessa, che viene eseguita controllando i tempi di consegna ed i costi preventivati.

COLLAUDO DIMENSIONALE

Certifichiamo la qualità dei componenti meccanici attraverso il reparto di collaudo interno.

STOCCAGGIO E GESTIONE LOGISTICA

Disponiamo di soluzioni logistiche e di immagazzinamento altamente automatizzate ed integrate. Ogni soluzione logistica adottata ha l’obiettivo di tracciare i materiali all’interno dello stabile, garantendo flessibilità e riduzione dei tempi di attraversamento.

ASSEMBLAGGIO MECCANICO

Sulla base dei disegni forniti, i tecnici specializzati di Logimatic procedono all’assemblaggio dei pezzi: la macchina automatica prende forma fino a risultare perfettamente funzionante e rispondere esattamente alle specifiche richieste dal Cliente.

COLLAUDO FINALE

Sulla macchina automatica costruita vengono eseguiti affidabili e specifici test di prova al fine di testarne il corretto funzionamento.

Lo straordinario

è di serie

Utilizziamo software gestionali all’avanguardia per gestire la logistica di inbound ed outbound. I nostri magazzini sono automatizzati ed interconessi al sistema gestionale.

Tramite strumenti di Business Analytics monitoriamo costantemente i KPI prefissati, in un’ottica di miglioramento continuo dei processi aziendali.